Popular keywords:

Contacts:Mr.Zhong

Email:121740864@qq.com

Phone:+86-138-1293-0229

ADD:579 Qianjin East Road, Kunshan Development Zone, Jiangsu Province

A.【Application】:

This machine is suitable for 8-shaped mesh forming of Class 5 and Class 6 cables, and meets the international advanced packaging technology requirements of the industry. Paper box packaging does not require wire reels, is easy to stack, can be freely laid out, does not twist, does not tie, is convenient to use, has a retractable linkage, microcomputer control, and automatic precise length determination, and is currently the most advanced packaging method for network cables. The coil forming method does not require wire coils or cores, but directly involves multiple layers of cross winding of cables. After forming a circle, a wire hole is formed in the circle line. After installing the loop wire into the paper box, insert a plastic sleeve into the outlet hole, and the inner end of the cable can be released from the plastic sleeve without twisting or knotting.

B.【Technique Feature】:

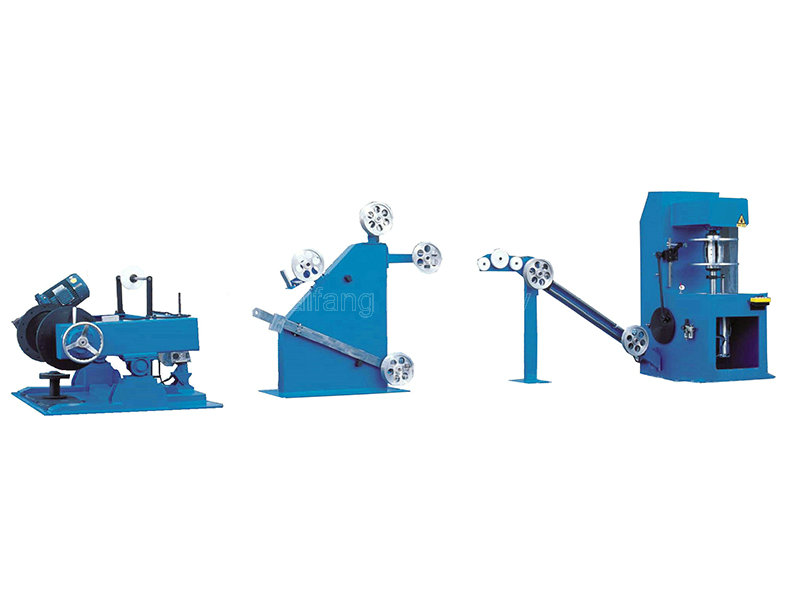

1. The loop forming machine is synchronized with the active pay-off rack to complete the mesh forming of network cables;

2. Servo motor wiring, PLC programming control, cross mesh uniform arrangement;

3. Reserve internal outlet holes to achieve non knotting and non twisting wire laying;

4. Standard packaging 305 meters (1000Ft) per roll;

5. The core size can be customized according to the packaging box;

C.【Technique Specifications】:

| Machinery type | TF-500 |

| Max speed | 3000rpm |

| Pay-off power | 5HP AC motor equipped with variable frequency speed regulation |

| Pay-off tension | Swing arm adjustable counterweight |

| Spool loading and unloading | Motor lifting or hydraulic lifting |

| Line power | 1.5KW servo motor |

| Traverse method | Linear sliding rail type |

| Meter counting method | Photoelectric induction type |

| Host power | 3KW DC motor |

| Electric control | Variable frequency speed control+PLC control |

| Machine Color | Bean green (can be specified by the customer) |